In fact, far more work is going on to build the sustainability of passenger shipping, but it appears the cruise industry has been less than effective at communicating its environmental credentials to the world.

Part of the challenge is of course that a ship has such a long life, which means a substantial percentage of the world cruise fleet is always operating with older technology. Over this last year there has been a bit of a leap forward, as cruise lines reducing their monthly outlay during this period of inactivity have sold their older (more polluting) ships for scrap.

Just last month MSC took delivery of their newest ship, Virtuosa, with innovations including hybrid exhaust gas cleaning systems and selective catalytic reduction systems; wastewater treatment systems; shore-to-ship power connectivity; and an underwater radiated noise management system. Their vision is to achieve a 'zero-impact cruise operation'.

As for fuel usage, the technology is speeding forth at such a rate, it is hard for the cruise lines to know which way things are going to progress. As a result, their engineers work hard in conjunction with the shipyards to design ships sufficiently flexible and adaptable that they will be able to utilise whichever fuels emerge as the most sustainable. Currently liquefied natural gas (LNG) is a good compromise (especially if carbon capture techniques improve), but later they will need to convert to greener fuels: hydrogen, or even ammonia, or possibly synthetic LNG. Some fuels which are themselves carbon neutral may rely heavily on fossil fuels to produce them, so it looks like green hydrogen is the front runner.

Likewise the ports need to be able to offer the new fuels, as well as links to shoreside electric power, such as we see at the new cruise terminal at Southampton.

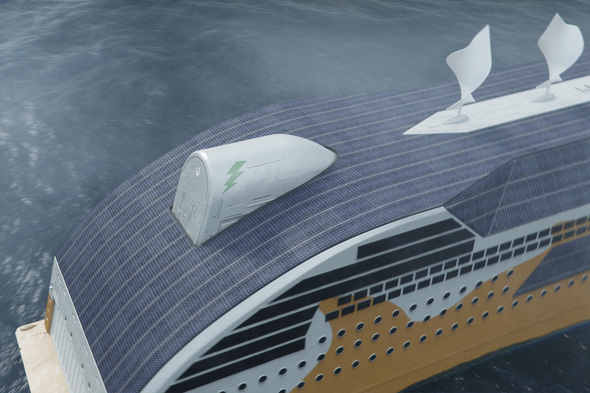

All of this requires huge investment, commitment and above all collaboration. An example of such a collaboration is the CHEK decarbonisation project, which will design two concept vessels: a bulk carrier, which will utilise sails to capture wind energy, and a cruise ship that will operate with a Wärtsilä-designed engine running on hydrogen fuel. Several decarbonisation technologies will be demonstrated, with system integration for both vessels, including hybridisation, energy storage and shore power connections. The partners in the collaboration include shipping giant MSC as well as vessel charterers, vessel operators, marine technology companies, designers and universities who will all work to deploy decarbonisation technology.

The shipping sector has set zero emissions and carbon neutrality as main targets. And whilst cruise ships account for only a tiny proportion of the world fleet (cruise ships make up less than 1% of the world's 50,000 commercial maritime vessels) they have a disproportionate impact on air quality, using more fuel (because of the energy needed to support hotel operations and leisure facilities) as well as operating close to the coastline.

It's not just about fuel of course. The sudden growth in expedition new builds has seen the cruise industry at the forefront of innovative technological developments which can be embraced across the sector.

In China, SunStone Ships' expedition cruise ships feature the X-BOW hull design which doesn't slam and brake in bad weather, making their ships more fuel-efficient and more comfortable for the passenger too. Ponant's icebreaker Le Commandant Charcot, currently being built at the Vard shipyard and due for delivery in April, will be the world's first cruise ship built to PC2-class as an icebreaker, and the first expedition cruise ship to use dual-fuel liquefied natural gas (LNG). The vessel will also use batteries to provide the hotel load when it has stopped to observe something of interest, allowing the main engines to be turned off and the vessel to be silent, with no vibration.

Enova, a Norwegian government enterprise to promote clean energy, has supported Hurtigruten in its development of battery power for new builds Roald Amundsen and Fridtjof Nansen, the first expedition ships to sail with full hybrid capabilities, reducing emissions by as much as 20 percent. Excursions in Svalbard are to be operated by a hybrid catamaran, which can operate on electric power. We are seeing widespread adoption of ABB's innovative Azipod propulsion units, not just by expedition ships but also by Virgin Voyages, for example, which help cut fuel consumption by up to 15%.

Cold ironing - also known as shore connection, shore-to-ship power (SSP) or alternative maritime power (AMP) - is the process of providing shoreside electrical power to a ship at berth while its main and auxiliary engines are turned off. The Baltic ports in particular (take Kiel for example) are investing heavily in this technology to enhance the services they can provide to cruise ships.

There is plenty of investment by the cruise lines in retrofitting older ships, in particular with the installation of 'scrubber' or exhaust gas cleaning systems that help minimise emissions. This is currently the subject of a bitter dispute between the International Maritime Organisation and ten NGOs which have called for an immediate moratorium, challenging the cruise industry's assertion that this is the optimum way of reducing emissions of sulphur, black carbon, particulate matter and other noxious substances.

Quite apart from technological advances, we are seeing high levels of collaboration with agencies such as the International Association of Antarctic Tour Operators and the Association of Arctic Expedition Cruise Operators, as well as scientific projects whereby cruise lines report back with extensive marine data including ocean circulation dynamics.

And we haven't even started to talk about actions on board to recycle, incinerate, treat or process, all of which are now accepted as standard, nor the widely adopted ban on single use plastics. Nor indeed the well developed outreach and educational programmes and beach clean-ups, with the ultimate aim of ensuring that the positive benefits of taking people around the world by sea outweigh any negative impact.

There is quite a focus on Europe's rivers, with a new Green Award certification, which river cruise lines need to apply for. To earn this award, river cruise ships are evaluated on the environmental impact of their engines, fuel consumption, waste and maintenance, pollution prevention and more.

These include energy-saving LED lights, special insulated windows that reduce energy needs for heating and cooling, power locks to plug into a port's power supply instead of running generators, solar heating systems, water treatment plants that use a membrane technology to provide microfiltration and recycling of all water used on board. The Port of Amsterdam incentivises river cruise companies to achieve this award, in order to reduce the impact of visiting vessels.